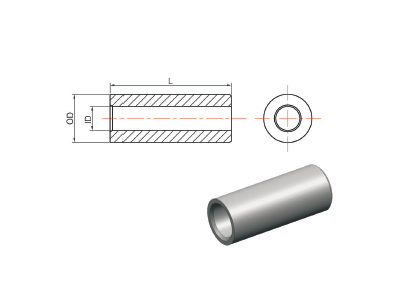

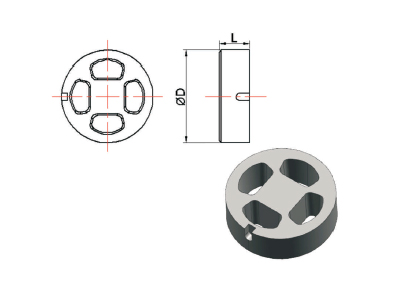

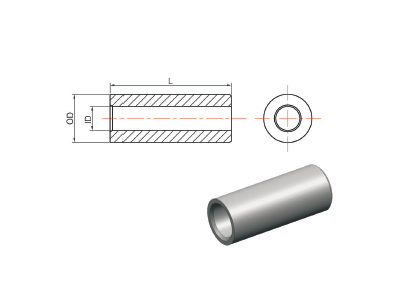

Carbide Trim and Ring

Solid carbide cage provides optimum wear

resistance in erosive conditions, used in

cage choke valve.

| Size |

Trim |

Ring |

| OD(mm) |

ID(mm) |

L(mm) |

OD(mm) |

ID(mm) |

L(mm) |

| 1" |

48.05 |

25.4 |

108.43 |

41.35 |

35.35 |

33.46 |

| 1.5" |

67.32 |

38.1 |

125.45 |

57.27 |

51.11 |

55.8 |

| 2" |

76.19 |

50.8 |

134.58 |

69.9 |

63.98 |

63.09 |

| 3" |

112.93 |

76.2 |

154.66 |

105.02 |

95.58 |

85.3 |

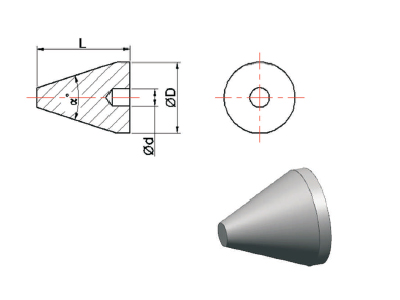

Choke Bean

Carbide choke valve bean has anti-corrosion,

anti-erosion, and impact resistant properties,

giving lasting endurance in high pressure, and

high temperature working conditions.

| Size |

OD(inch) |

OD(mm) |

ID(inch) |

ID(mm) |

L(inch) |

L(mm) |

| 2/64" |

0.650 |

16.510 |

0.031 |

0.787 |

5.880 |

149.352 |

| 4/64" |

0.062 |

1.575 |

| 6/64" |

0.093 |

2.362 |

| 8/64" |

0.125 |

3.175 |

| 10/64" |

0.650 |

16.510 |

0.156 |

3.962 |

| 12/64" |

0.187 |

4.750 |

| 14/64" |

0.218 |

5.537 |

| 16/64" |

0.250 |

6.350 |

| 18/64" |

0.945 |

24.003 |

0.281 |

1.137 |

| 20/64" |

0.312 |

7.925 |

| 22/64" |

0.343 |

8.712 |

| 24/64" |

0.375 |

9.525 |

| 26/64" |

0.945 |

24.003 |

0.406 |

10.312 |

| 28/64" |

0.437 |

11.100 |

| 30/64" |

0.468 |

11.887 |

| 32/64" |

0.500 |

12.700 |

| 34/64" |

1.181 |

29.998 |

0.531 |

13.487 |

| 36/64" |

0.562 |

14.275 |

| 38/64" |

0.593 |

15.062 |

| 40/64" |

0.625 |

15.875 |

| 42/64" |

1.181 |

29.998 |

0.656 |

16.662 |

| 44/64" |

0.687 |

17.150 |

| 46/64" |

0.718 |

18.237 |

| 48/64" |

0.750 |

19.050 |

| 50/64" |

1.339 |

34.011 |

0.781 |

19.837 |

| 52/64" |

0.812 |

20.625 |

| 54/64" |

0.843 |

21.412 |

| 56/64" |

0.875 |

22.225 |

| 58/64" |

1.417 |

35.992 |

0.906 |

23.012 |

| 60/64" |

0.937 |

23.800 |

| 62/64" |

0.968 |

24.587 |

| 64/64" |

1.000 |

25.400 |

| 66/64" |

1.625 |

41.275 |

1.031 |

26.187 |

| 68/64" |

1.062 |

26.975 |

| 70/64" |

1.093 |

27.762 |

| 72/64" |

1.125 |

28.575 |

| 74/64" |

1.625 |

41.275 |

1.156 |

29.362 |

| 76/64" |

1.187 |

30.150 |

| 78/64" |

1.218 |

30.940 |

| 80/64" |

1.772 |

45.009 |

1.250 |

31.750 |

| 82/64" |

1.281 |

32.537 |

| 84/64" |

1.312 |

33.325 |

| 86/64" |

1.343 |

34.112 |

| 88/64" |

1.375 |

34.925 |

| 90/64" |

1.909 |

48.489 |

1.406 |

35.712 |

| 92/64" |

1.437 |

36.500 |

| 94/64" |

1.468 |

37.287 |

| 96/64" |

1.500 |

38.100 |

| 98/64" |

2.047 |

51.994 |

1.531 |

38.887 |

| 100/64" |

1.562 |

39.675 |

| 102/64" |

1.563 |

39.700 |

| 104/64" |

1.625 |

41.275 |

| 106/64" |

2.165 |

54.991 |

1.656 |

42.062 |

| 108/64" |

1.687 |

42.850 |

| 110/64" |

1.718 |

43.637 |

| 112/64" |

1.750 |

44.450 |

| 114/64" |

2.283 |

57.988 |

1.781 |

45.237 |

| 116/64" |

1.812 |

46.025 |

| 118/64" |

1.843 |

46.812 |

| 120/64" |

1.875 |

47.625 |

| 124/64" |

2.402 |

61.0108 |

1.937 |

49.200 |

| 126/64" |

1.968 |

49.987 |

| 128/64" |

2.000 |

50.800 |

| 136/64" |

2.913 |

73.9902 |

2.125 |

53.975 |

| 144/64" |

2.250 |

57.150 |

| 152/64" |

2.375 |

60.325 |

| 160/64" |

2.500 |

63.500 |

| 168/64" |

3.405 |

86.487 |

2.625 |

66.675 |

| 176/64" |

2.750 |

69.850 |

| 184/64" |

2.875 |

73.025 |

| 192/64" |

3.000 |

76.200 |

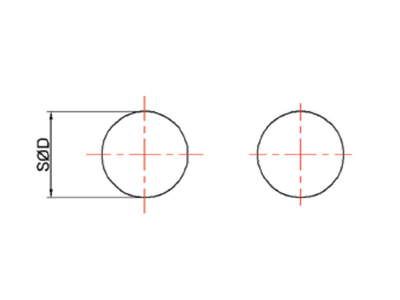

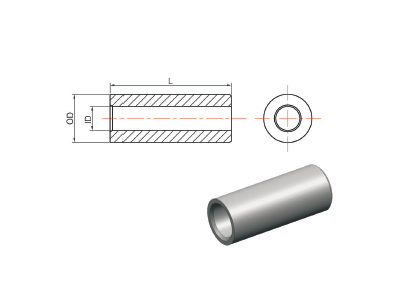

Valve Disk

The valve disk is widely used in choke valve

and control valve to accurately control

the volume and pressure of fluid.

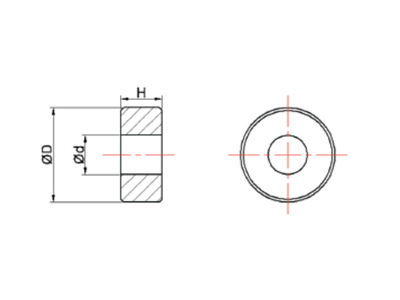

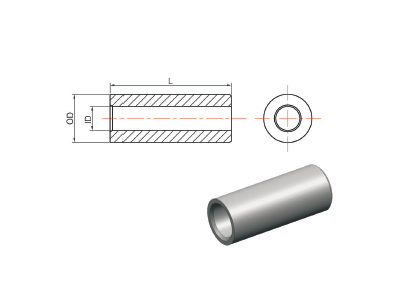

Valve ball & seat

| API Ball |

OD(inch) |

OD(mm) |

| V11-106 |

5/8 |

15.875 |

| V11-125 |

3/4 |

19.05 |

| V11-150 |

15/16 |

23.8125 |

| V11-175 |

1-1/8 |

28.575 |

| V11-225 |

1-3/8 |

34.925 |

| V11-250 |

1-11/16 |

42.8625 |

| V11-375 |

2-1/4 |

57.15 |

| API Seat |

OD(inch) |

OD(mm) |

ID(inch) |

ID(mm) |

L(inch) |

L(mm) |

| V11-106 |

0.793 |

20.142 |

0.468 |

11.89 |

0.5 |

12.7 |

| V11-125 |

0.918 |

23.317 |

0.575 |

14.61 |

0.5 |

12.7 |

| V11-150 |

1.168 |

29.667 |

0.702 |

17.83 |

0.5 |

12.7 |

| V11-175 |

1.388 |

35.255 |

0.830 |

21.08 |

0.5 |

12.7 |

| V11-225 |

1.720 |

43.688 |

1.046 |

26.57 |

0.5 |

12.7 |

| V11-250 |

2.010 |

51.054 |

1.265 |

32.13 |

0.5 |

12.7 |

| V11-375 |

3.072 |

78.029 |

1.752 |

44.5 |

0.75 |

19.05 |

Flow control points & shell points

As per your request to provide carbide

wear parts or turn key service-accessory

that can used directly.

Carbide nozzle has better wear resistance and corrosion\erosion resistance, resists the wear of the nozzle under high

liquid pressure, and can improve the life of the nozzle.

Nozzles for drill bits

- Threaded nozzle of plumblossom teeth wrench series

- Threaded nozzle of inner hexagon wrench series

- Threaded nozzle of hexagon wrench series

- Threaded nozzle of castle top wrench series

- Mud nozzle

Customized nozzle

As per your request to provide customized material and geometry nozzles.

Customized nozzle

Carbide choke valve bean has anti-corrosion,

anti-erosion, and impact resistant properties,

giving lasting endurance in high pressure, and

high temperature working conditions.

| Size |

OD(inch) |

OD(mm) |

ID(inch) |

ID(mm) |

L(inch) |

L(mm) |

| 2/64" |

0.650 |

16.510 |

0.031 |

0.787 |

5.880 |

149.352 |

| 4/64" |

0.062 |

1.575 |

| 6/64" |

0.093 |

2.362 |

| 8/64" |

0.125 |

3.175 |

| 10/64" |

0.650 |

16.510 |

0.156 |

3.962 |

| 12/64" |

0.187 |

4.750 |

| 14/64" |

0.218 |

5.537 |

| 16/64" |

0.250 |

6.350 |

| 18/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 20/64" |

|

|

| 22/64" |

|

|

| 24/64" |

|

|

| 26/64" |

|

|

0.031 |

0.787 |

|

|

| 28/64" |

|

|

| 30/64" |

|

|

| 32/64" |

|

|

| 34/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 36/64" |

|

|

| 38/64" |

|

|

| 40/64" |

|

|

| 42/64" |

|

|

0.031 |

0.787 |

|

|

| 44/64" |

|

|

| 46/64" |

|

|

| 48/64" |

|

|

| 50/64" |

|

|

|

|

|

|

| 52/64" |

|

|

| 54/64" |

|

|

| 56/64" |

|

|

Wear protection carbide inserts for stabilizer

Carbide choke valve bean has anti-corrosion,

anti-erosion, and impact resistant properties,

giving lasting endurance in high pressure, and

high temperature working conditions.

| Size |

OD(inch) |

OD(mm) |

ID(inch) |

ID(mm) |

L(inch) |

L(mm) |

| 2/64" |

0.650 |

16.510 |

0.031 |

0.787 |

5.880 |

149.352 |

| 4/64" |

0.062 |

1.575 |

| 6/64" |

0.093 |

2.362 |

| 8/64" |

0.125 |

3.175 |

| 10/64" |

0.650 |

16.510 |

0.156 |

3.962 |

| 12/64" |

0.187 |

4.750 |

| 14/64" |

0.218 |

5.537 |

| 16/64" |

0.250 |

6.350 |

| 18/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 20/64" |

|

|

| 22/64" |

|

|

| 24/64" |

|

|

| 26/64" |

|

|

0.031 |

0.787 |

|

|

| 28/64" |

|

|

| 30/64" |

|

|

| 32/64" |

|

|

| 34/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 36/64" |

|

|

| 38/64" |

|

|

| 40/64" |

|

|

| 42/64" |

|

|

0.031 |

0.787 |

|

|

| 44/64" |

|

|

| 46/64" |

|

|

| 48/64" |

|

|

| 50/64" |

|

|

|

|

|

|

| 52/64" |

|

|

| 54/64" |

|

|

| 56/64" |

|

|

Carbide Accessories

Carbide choke valve bean has anti-corrosion,

anti-erosion, and impact resistant properties,

giving lasting endurance in high pressure, and

high temperature working conditions.

| Size |

OD(inch) |

OD(mm) |

ID(inch) |

ID(mm) |

L(inch) |

L(mm) |

| 2/64" |

0.650 |

16.510 |

0.031 |

0.787 |

5.880 |

149.352 |

| 4/64" |

0.062 |

1.575 |

| 6/64" |

0.093 |

2.362 |

| 8/64" |

0.125 |

3.175 |

| 10/64" |

0.650 |

16.510 |

0.156 |

3.962 |

| 12/64" |

0.187 |

4.750 |

| 14/64" |

0.218 |

5.537 |

| 16/64" |

0.250 |

6.350 |

| 18/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 20/64" |

|

|

| 22/64" |

|

|

| 24/64" |

|

|

| 26/64" |

|

|

0.031 |

0.787 |

|

|

| 28/64" |

|

|

| 30/64" |

|

|

| 32/64" |

|

|

| 34/64" |

0.650 |

16.510 |

0.031 |

0.787 |

|

|

| 36/64" |

|

|

| 38/64" |

|

|

| 40/64" |

|

|

| 42/64" |

|

|

0.031 |

0.787 |

|

|

| 44/64" |

|

|

| 46/64" |

|

|

| 48/64" |

|

|

| 50/64" |

|

|

|

|

|

|

| 52/64" |

|

|

| 54/64" |

|

|

| 56/64" |

|

|