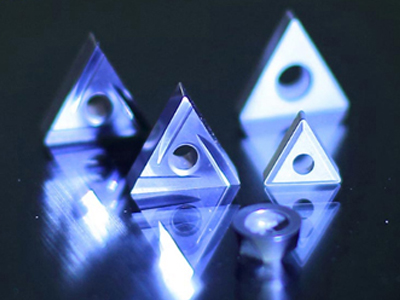

Cermet inserts

Cermet inserts

Cermet grades are developed by authoritative Japanese technical team. Adopt TiC+TiCN as major contents.

Lifetime of Cermet is about 3-10 times of normal carbide.

Products include Inserts, Rods, Saw Teeth.

Features

1. The entire R&D on cermet inserts grades leads by our experienced Japanese technical team.Adopt Tic+TiCN as the major contents.

2. With features of excellent wear resistance,red hardness,chemical durability and lower friction coefficient,that makes the lifetime of Cermet is about 3-10 times of normal carbide.

3. Cermet is getting more popular for metalworking tools when the job requires high speed,high precision,high efficiency and fine finish.

Specification

| Grade |

Density ±0.2g/cm³ |

T.R.S >N/mm³ |

Hardness ±0.2HRA |

Applications |

| Processing methods |

ISO classification |

| CMT 60 |

7 |

2000 |

92.3 |

Finishing |

P01-P10,M01-M10 |

| CMT 70 |

7.1 |

2100 |

91.8 |

Finishing、Semi-finishing |

P05-P20,M05-M20,K10-K15 |

| CMT 80 |

7.3 |

2250 |

90.6 |

Semi-finishing、Medium-rough |

P10-P25,M10-M25 |

Cermet rod

Cermet rod

Cermet rod (ceramic rod) grades are developed by authoritative Japanese technical team. Adopt TiC+TiCN as the major contents.

Lifetime of Cermet is about 3-10 times of normal carbide.

Products include Inserts, Rods, Saw Teeth.

Features

1. The entire R&D on cermet rod grades leads by our experienced Japanese technical team.Adopt Tic+TiCN as the major contents.

2. With features of excellent wear resistance,red hardness,chemical durability and lower friction coefficient,that makes the lifetime of Cermet is about 3-10 times of normal carbide.

3. Cermet is getting more popular for metalworking tools when the job requires high speed,high precision,high efficiency and fine finish.

Specification

| Grade |

Density ±0.2g/cm³ |

T.R.S >N/mm³ |

Hardness ±0.2HRA |

| CMT 60 |

7 |

2000 |

92.3 |

| CMT 70 |

7.1 |

2100 |

91.8 |

| CMT 80 |

7.3 |

2250 |

90.6 |

| Grade |

Applications |

| Processing methods |

ISO classification |

| CMT 60 |

Finishing |

P01-P10,M01-M10 |

| CMT 70 |

Finishing、Semi-finishing |

P05-P20,M05-M20,K10-K15 |

| CMT 80 |

Semi-finishing、Medium-rough |

P10-P25,M10-M25 |

Cermet saw tips

Cermet saw tips

Cermet grades are developed by authoritative Japanese technical team. Adopt TiC+TiCN as major contents.

Lifetime of Cermet is about 3-10 times of normal carbide.

Products include Inserts, Rods, Saw Teeth.

Features

Advantages of Our Carbide Wire Drawing Die :

1. The entire R&D on cermet saw tips grades leads by our experienced Japanese technical team.Adopt Tic+TiCN as the major contents.

2. With features of excellent wear resistance,red hardness,chemical durability and lower friction coefficient,that makes the lifetime of Cermet is about 3-10 times of normal carbide.

3. Cermet is getting more popular for metalworking tools when the job requires high speed,high precision,high efficiency and fine finish.

Specification

Grades for Molding Industry

| Grade |

Density ±0.2g/cm³ |

T.R.S >N/mm³ |

Hardness ±0.2HRA |

Applications |

| Processing methods |

ISO classification |

| CMT 60 |

7 |

2000 |

92.3 |

Finishing |

P01-P10,M01-M10 |

| CMT 70 |

7.1 |

2100 |

91.8 |

Finishing、Semi-finishing |

P05-P20,M05-M20,K10-K15 |

| CMT 80 |

7.3 |

2250 |

90.6 |

Semi-finishing、Medium-rough |

P10-P25,M10-M25 |