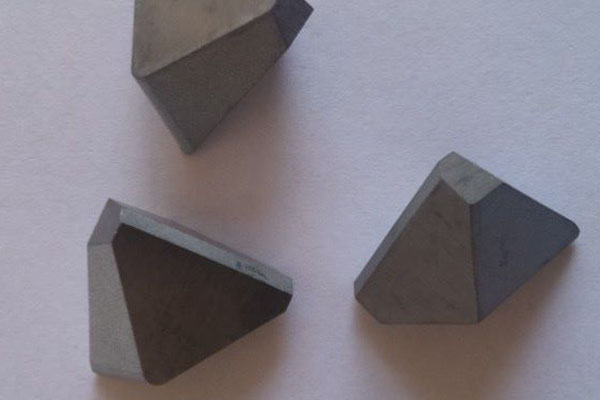

Tungsten carbide insert blanks with very complex shape and design, developed for machining of refractory bricks used in furnaces.

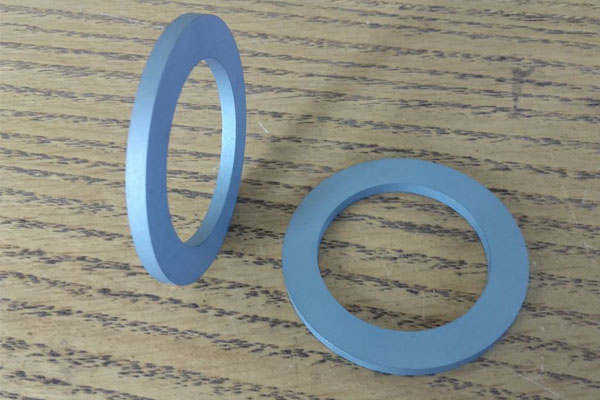

Solid Carbide Slitting Saw Blanks Dia. 52 x Thk 2.8 x Bore Dia 38 with just 0.5 mm allowance all over. No wire cutting required. Brings down machining and through put time by 80%.

Our moment of pride!!! Recently we developed Tungsten Carbide Seal for Concrete Pumps. The cross section size is 550 mm long x 250 mm width and a wall thickness of 5 mm.

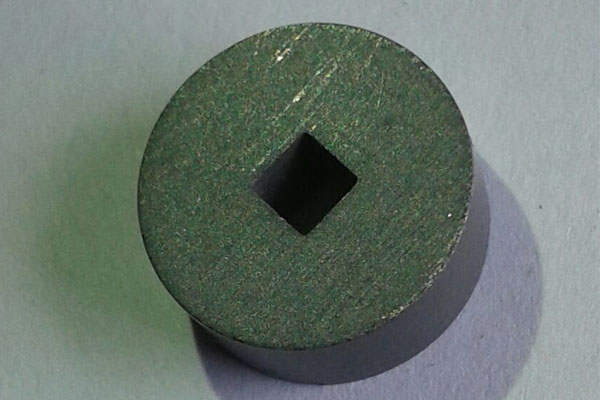

Solid Carbide guide Bush With Square Hole in Sintered and Unground Condition.

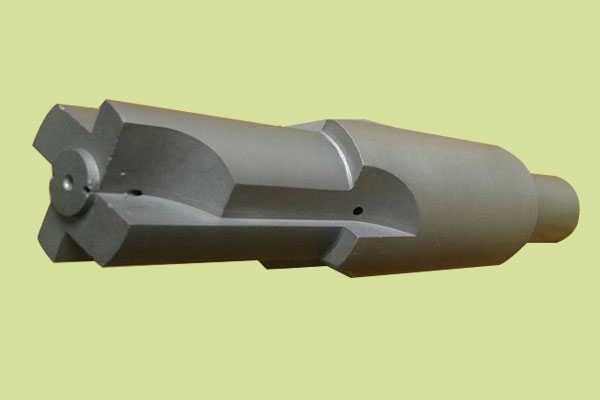

Another innovation. Preforms for solid carbide step drills but this time customer wanted female centre at one end and male centre on the drill point.

Tungsten carbide core for military applications

Our latest development Solid Carbide Drill pre-form for 3 fluted drills dia. 32 mm x 160 mm flute length x 25 mm shank dia with ready thru coolant holes for all 3 flutes.

Solid Carbide Setp Drill Perform Blank With Two Coolant Hole in Sintered and Unground Condition

Trial phase launch of Cermet Rods for manufacturing round tools for the die and mold segment and hard part milling (above 55 HRC hardness molds).

Carbide preform blank in sintered unground condition. Saves blank cost and reduces machining time drastically.

Getting tungsten carbide shims to required shape and form has always been an issue for all spare manufacturers.

Solid Carbide Performs with coolant Holes at 3 steps in Sintered and unground condition, Grindng allowance 0.5 MM on All Sides

Cutting conditions are very extreme with total contact depth as much as 15 mm deep and dry cutting condition without any type of coolant.

The rear wheel transmission of all vehicles will have a crown wheel and a pinion, hese blades are used to cut face teeth on forged blanks of the crown and the pinion.