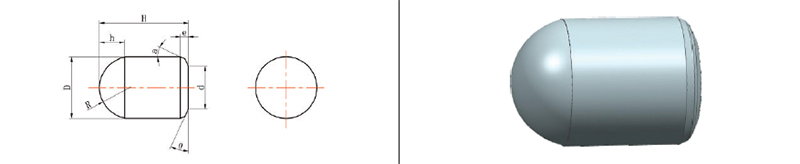

Carbide Button Inserts

Carbide Button Inserts

| Series |

Grades |

Binder % |

Grain Size |

Density |

Hardness |

T.R.S |

| g / cm3 |

HRA |

HV30 |

≥ N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 20 |

8.0 |

Coarse |

14.8 |

89.0 |

1250 |

2800 |

| CE 10T |

6.5 |

Extra Coarse |

14.9 |

87.3 |

1090 |

2500 |

| CE 40T |

10.0 |

14.5 |

85.5 |

950 |

2800 |

| Economic |

CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |

1. BTC offers a wide ranges of grades with proved excellent performance, i.e. the superior grade BTCR10 for hard and super hard rock, BTCE20 for complex

medium soft rock, BTCE40T for coal mining.

2. Economic grades are also the good options for cost sensitive projects with above average performance.

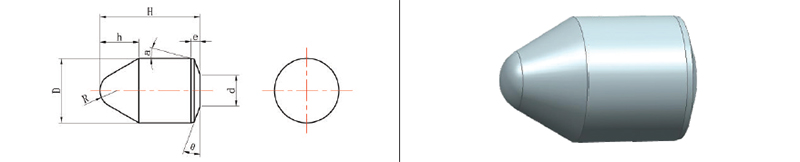

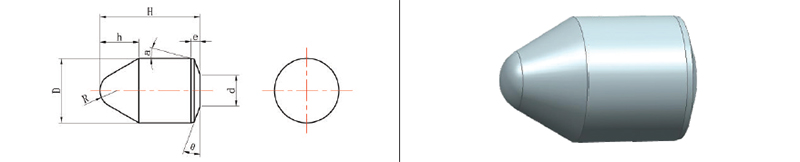

Specification :

( Conical )

Carbide Button Inserts

| Series |

Grades |

Binder % |

Grain Size |

Density |

Hardness |

T.R.S |

| g / cm3 |

HRA |

HV30 |

≥ N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 20 |

8.0 |

Coarse |

14.8 |

89.0 |

1250 |

2800 |

| CE 10T |

6.5 |

Extra Coarse |

14.9 |

87.3 |

1090 |

2500 |

| CE 40T |

10.0 |

14.5 |

85.5 |

950 |

2800 |

| Economic |

CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |

Product advantages of tungsten carbide buttons tips :

1. efficient processing, good high-temperature stability.

2. easy to weld, no crack or chipping.

3. smooth surface of stone after processing

( Specification )

Carbide Button Inserts -- Conical

| TYPE |

D |

H |

| BC0711 |

7.2 |

11 |

| BC0812 |

8.2 |

12 |

| BC09145 |

9.2 |

14.5 |

| BC1013 |

10.2 |

13 |

| BC1015 |

10.2 |

15 |

| BC1016 |

10.2 |

16 |

| BC1017 |

10.2 |

17 |

| BC1216 |

12.2 |

16 |

| BC1218 |

12.2 |

18 |

| BC1219 |

12.2 |

19 |

| BC1221 |

12.2 |

21 |

| BC1319 |

13.2 |

19 |

| BC1321 |

13.2 |

21 |

| BC1419 |

14.3 |

19 |

| BC1420 |

14.3 |

20 |

| BC1424 |

14.3 |

24 |

| BC1625 |

16.3 |

25 |

| BC1628 |

16.3 |

28 |

( Chiesel )

Carbide Button Inserts

| Series |

Grades |

Binder % |

Grain Size |

Density |

Hardness |

T.R.S |

| g / cm3 |

HRA |

HV30 |

≥ N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 20 |

8.0 |

Coarse |

14.8 |

89.0 |

1250 |

2800 |

| CE 10T |

6.5 |

Extra Coarse |

14.9 |

87.3 |

1090 |

2500 |

| CE 40T |

10.0 |

14.5 |

85.5 |

950 |

2800 |

| Economic |

CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |

Details of productions :Carbide button

1. high stability, long life circle

2. good abrasive and corrosion resistance

3. high quality and high hardness

4. purity without recycled material

5. fast delivery

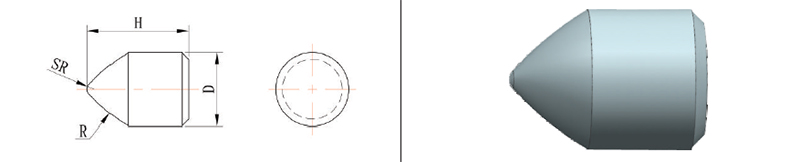

Cabide Inserts For Tunnel Boring

Cabide Inserts For Round Shank Picks

| Series |

Grades |

Binder % |

Grain Size |

Density |

Hardness |

T.R.S |

| g / cm3 |

HRA |

HV30 |

≥ N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 20 |

8.0 |

Coarse |

14.8 |

89.0 |

1250 |

2800 |

| CE 10T |

6.5 |

Extra Coarse |

14.9 |

87.3 |

1090 |

2500 |

| CE 40T |

10.0 |

14.5 |

85.5 |

950 |

2800 |

| Economic |

CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |

1. Facing the critical drilling chanllenges,CY offers a wide ranges of grades whth approced excelllent performance,i.e.the superior grade CR10 for hard and super hard rock,CE20 for complex medium soft rock,CE40T for coal mining.

2. Economic grades are also the good options for cost sensitive projects with above average performance.

Specification

<

| TYPE |

D |

H |

| BM1424 |

15 |

24 |

| BM17522 |

17.5 |

22 |

| BM17524 |

17.5 |

24 |

| B17529 |

17.5 |

29 |

| BM1926 |

19 |

26 |

| BM1928 |

19 |

28 |

| BM2128 |

21 |

28 |

| BM2228 |

22 |

28 |

| BM2230 |

22 |

30 |

| BM2234 |

22 |

34 |

| BM2534 |

25 |

34 |

| BM3040 |

30 |

40 |

Carbide Inserts for Round Shank Picks

| Series |

Grades |

Binder % |

Grain Size |

Density |

Harndess |

T.R.S |

| ± 0.1g / cm3 |

± 0.3 HRA |

± 50 HV30 |

> N / mm2 |

| Premium |

CE 60 |

11.5 |

Coarse |

14.4 |

87.0 |

1070 |

2850 |

| CE 80 |

12.5 |

14.3 |

86.5 |

1030 |

2850 |

| CE 90 |

15.0 |

14.0 |

85.5 |

950 |

2900 |

| Economic |

CK 401 |

11.0 |

Coarse |

14.3 |

87.5 |

1110 |

2600 |

| CK 402 |

15.0 |

14.0 |

86.5 |

1030 |

2700 |

Submicro Grain Size, with all HIP treatmemt

Our Service

1. The grades of our TBM inserts achinevedideal balance between wearing and impacting,moreover with excellent corrossion resistance.

2. In additon to the regular directly pressing,our unique Preforming Process (CIP) prefectly suits the order characties of TBM inserts which is widely known as "complicate,diversified,changeful and in small batch"

Microstructure of TBL Insert

1. The grades of our TBM inserts achieved ideal balance between wearing and impacting,moreover with

excellent corrossion resistance.

2. In additon to the regular directly pressing, our unique Preforming Process (CIP) prefectly suits the order characties of TBM inserts which is widely known as "complicate, diversified,changeful and in small batch"

Carbide Crushing Blades

| Series |

Grades |

Binder % |

Grain Size |

Density |

Harndess |

T.R.S |

| ± 0.1g / cm3 |

± 0.3 HRA |

± 50 HV30 |

> N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 40 |

9.5 |

14.5 |

88.0 |

1160 |

2800 |

| CE 60 |

11.5 |

14.4 |

87.0 |

1070 |

2850 |

| Economic |

CK 10H |

6.0 |

Medium - Fine |

14.9 |

91.3 |

1500 |

2300 |

| CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |

Carbide Scraper For Conveyor System

| Series |

Grades |

Binder % |

Grain Size |

Density |

Harndess |

T.R.S |

| ± 0.1 g / cm3 |

± 0.3 HRA |

±50 HV 30 |

> N / mm2 |

| Premium |

SK 10 |

9 . 5 (Co+Ni) |

Submicron |

14.5 |

92.0 |

1610 |

3000 |

| SK 30 |

10 . 0 (Ni) |

14.4 |

91.0 |

1470 |

2500 |

Features Of Carbide Crushing Blades :

1. Tungsten carbide strips are usually used for general wood cutters / hard wood cutters ,plastic and tobacco cutting . and meet the ISO9001:2015 quanlity

standard. We can make the shipment in the shortest delivery time wtih the compeititve price than any other factory

.

2.We can manufacture various cemented carbide stipes and plate as per customer's requirments based on the differente markets. Our main products

include :Cemented carbide drills, cutting cutters, mining tools, drawing dies ,carbide stripes ,rods etc.

3. Skillful workers and advanced euquipments can make every of your size possible.

4. Different grade are available too.

5. We take great efforts to increase commodity types rather than quantitiy to promote the flexibility of competing in the worldmarket. Above all , our client;s

demands are always the first to be considered.

| Series |

Grades |

Binder % |

Grain Size |

Density |

Harndess |

T.R.S |

| ± 0.1 g / cm3 |

± 0.3 HRA |

±50 HV 30 |

> N / mm2 |

| Premium |

SK 10 |

9 . 5 (Co+Ni) |

Submicron |

14.5 |

92.0 |

1610 |

3000 |

| SK 30 |

10 . 0 (Ni) |

14.4 |

91.0 |

1470 |

2500 |

Size

| L |

W |

T |

| 50 |

8 |

2 |

| 50 |

10 |

2 |

| 50 |

10 |

3 |

| 100 |

8 |

2 |

| 100 |

10 |

2 |

| 100 |

10 |

3 |

| 150 |

8 |

2 |

| 150 |

10 |

2 |

| 150 |

10 |

3 |

| 120 |

12 |

2 |

| 120 |

20 |

2 |

| 120 |

20 |

4 |

1. Tungsten carbide strips are usually used for general wood cutters / hard wood cutters ,plastic and tobacco cutting . and meet the ISO9001:2015 quanlity

standard. We can make the shipment in the shortest delivery time wtih the compeititve price than any other factory

.

2.We can manufacture various cemented carbide stipes and plate as per customer's requirments based on the differente markets. Our main products

include :Cemented carbide drills, cutting cutters, mining tools, drawing dies ,carbide stripes ,rods etc.

3. Skillful workers and advanced euquipments can make every of your size possible.

4. Different grade are available too.

5. We take great efforts to increase commodity types rather than quantitiy to promote the flexibility of competing in the worldmarket. Above all , our client;s

demands are always the first to be considered.

| Series |

Grades |

Binder % |

Grain Size |

Density |

Harndess |

T.R.S |

| ± 0.1g / cm3 |

± 0.3 HRA |

± 50 HV30 |

> N / mm2 |

| Premium |

CR 10 |

6.0 |

Medium |

14.9 |

90.7 |

1430 |

2800 |

| CE 40 |

9.5 |

14.5 |

88.0 |

1160 |

2800 |

| CE 60 |

11.5 |

14.4 |

87.0 |

1070 |

2850 |

| Economic |

CK 10H |

6.0 |

Medium - Fine |

14.9 |

91.3 |

1500 |

2300 |

| CK 301 |

8.0 |

Coarse |

14.7 |

89.0 |

1250 |

2450 |

| CK 401 |

11.0 |

14.3 |

87.5 |

1110 |

2600 |